Hydraulic cylinders

We are specialized in designing and manufacturing of Hydraulic Cylinders which are according to your task, your equipments and your specifications.

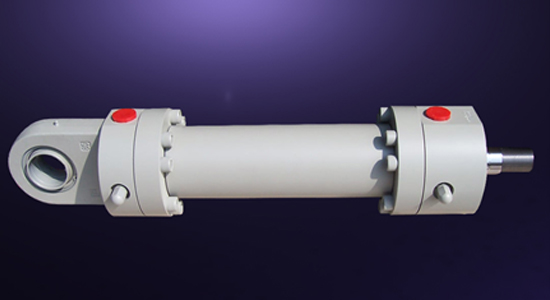

Mill Type Hydraulic Cylinders

- Mill type hydraulic cylinders are reliable drive elements and particularly suitable for use under extreme working conditions. General mechanical engineering, rolling mills and smelting works, presses, cranes, steel construction for hydraulic engineering or shipbuilding are typical fields of application. The Radiance mill type hydraulic cylinder range comprises both, screwed and welded cylinders. In which welded cylinders distinguish themselves by their short, compact design.

- Radiance Hydraulics manufacture special types of induction hardened piston rods which is used for longer life of piston rods at critical applications and temperatures.

- Cylinder tube from St 52.0 as per DIN 2391/ 2393 Imported from world's best producers.

- Piston Rod of Ck-45 Hard Chrome Plated & Ground to Surface finish of 0.2 micron Ra or better, Chromium thickness of min. 20 micron on radius, Corrossion Resistance with rating 9 of NSS 100 hrs. rating. These rod rods are sourced from the world's best producers.

- We manufacture complete Stainless steel cylinders which gives better life to cylinders at higher temperatures.

Tie rod Cylinders

The tie rod hydraulic cylinders are primarily used in the machine tool industry and in production equipment of the automobile industry. Due to their little installation dimensions, hydraulic tie rod cylinders - similar to welded mill type hydraulic cylinders - can be used in very limited installation spaces.

Telescopic hydraulic cylinders

- ♦ Single acting telescopic cylinder

- ♦ Double acting telescopic cylinder

Radiance Hydraulics Telescopic Cylinders are engineered to achieve truer and smoother operation in heavy duty applications. Our fully welded type construction, which incorporates a generous lap between stages for more stability and rigidity, allows our cylinders to have a higher stress and side-loading threshold.

Hollow rod hydraulic cylinders

Hollow chrome rod or tubing rod hydraulic cylinders offer increased yield strength, reduced weight and material cost. Most commonly used in hydraulic cylinder designs for lifting equipment such as Auto Lifts, Roll Off Trucks, Scissor Lifts etc.

Pneumatic cylinders

These cylinders are manufactured to a high degree of precision and come with a wide variety of mounting style options which include Double trunnion mounting, Single trunnion mounting, Front plate mounting, Rear plate mounting, Leg mounting, Hinge mounting etc.

Air cylinders are pneumatic linear actuators driven by pressure differential in the cylinder chambers. Compressed gas (typically air) acts as the power to impart a force and cause actuation. The compressed gas is allowed to expand due to the pressure gradient, and forces a piston to move in the desired direction. One side of a piston flange can be pressurized to provide force and motion with a spring (providing return force after pressure is released), or both sides can be alternately pressurized for bi-directional powered motion.

Air cylinders are used in applications which push, pull, and lift objects, close doors, or hold, remove, and position parts. They are commonly used in materials handling and processing. Air cylinders are also important in fail safe systems.

Hydraulic Power Pack

We are engaged in manufacturing and supplying Hydraulic SPM Power Pack. These power packs are efficiently manufactured by our experienced professionals using premium quality raw material. Radiance Hydraulics custom builds hydraulic power packs for user specifications. The power packs are built with hydraulic elements of reputed makes with international mounting and manifold style valve assembly. Power packs with proportional/servo valves and variable displacement pumps are available. They can be provided with the electrical relay/PLC/CNC control systems too. Complete turnkey projects are undertaken. Power packs for special applications in pharmaceutical and food processing industry, process industry, construction industry, steel mills, etc. can be built.

In addition, we also undertake reconditioning, retrofitting and upgrading of customer's hydraulic systems.

Features :

- High quality

- Less maintenance

- Affordable price

Hydraulic Spares

Special purpose machines

Radiance Hydraulics manufactures all kind of machines for the special application purpose. We are completely equipped technically & commercially to manufacture the complete machine inhouse in the mentioned time frame.

We are dedicatedly engaged in manufacturing, supplying Special Purpose Machines. These machines are highly reliable as these are well tested for quality ensuring qualitative outcome at customer's end. These machines are widely demanded in automotive, packaging, die pressing, pipe testing machine, paver block industries etc. We manufacture these machine in under the supervision of expertise professionals making use of advance technology and motor tools. These machines are customized in accordance with customer's given specifications. Customers can avail these Special purpose machines from us. We also provide door-step delivery of these machines.

Here are the few names of the SPMs that we can manufacture

- Fly Ash Bricks Making SPM.

- Digital Fatigue Testing Machine for Spacer Damper.

- Horizontal Testing Machines With Load Cell.

- Metal Extrusion Presses.

- Cold forging SPM.

- Vacuum forming SPM.

- Carpet forming SPM.

- Drilling SPM.

- Number punching SPM.

- Linear & Rotary Indexing Machines

- Reverse welding SPM.

- Flange up SPM.

- Molding SPM.

- Banjo Straightening SPM.

- Knurling SPM.

- Welding fixture for automobile application.

- Hydraulic & pneumatic cylinders.

- Automation for material loading, pushing, shifting & unloading system for continuous type of Hardening & Tempering furnace for heavy forging components.

- Part ejection SPM for Forging press.

- And Many More...

Download Brochure

Download Brochure